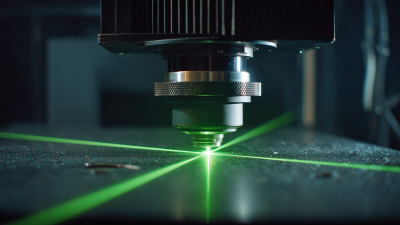

Exploring the Benefits of Fiber Laser Cutters in Modern Manufacturing Techniques

In recent years, the adoption of fiber laser cutters has revolutionized the landscape of modern manufacturing techniques, enabling unprecedented levels of precision and efficiency. According to a report by Market Research Future, the global fiber laser market is projected to grow at a CAGR of 10% from 2021 to 2027, driven by increasing demand across various sectors including automotive, aerospace, and electronics. The fiber laser cutter, known for its ability to cut through a variety of materials with minimal waste and improved speed, offers manufacturers the capability to enhance productivity while reducing operational costs.

As industries increasingly prioritize sustainability and lower turnaround times, the integration of fiber laser technology is becoming a critical component in achieving these goals. With the capacity to produce intricate designs and those complex geometries that traditional cutting methods struggle with, fiber laser cutters are not only increasing manufacturing efficiency but also pushing the boundaries of innovation in the field.

Advantages of Fiber Laser Cutters Over Traditional Laser Technologies in Manufacturing

Fiber laser cutters have emerged as a transformative technology in modern manufacturing, offering several advantages over traditional laser technologies, such as CO2 lasers. One major benefit is their efficiency; fiber lasers convert up to 80% of the electrical energy into usable laser light, compared to just around 25% for CO2 lasers. According to the Laser Institute of America, this high conversion rate translates into significant cost savings in energy consumption, making fiber laser cutters not only more eco-friendly but also more economically viable for manufacturers.

Moreover, fiber laser cutters boast superior cutting speed and precision. Industry reports highlight that fiber lasers can achieve cutting speeds up to three times faster than their CO2 counterparts while maintaining exceptional quality. They are particularly effective in cutting reflective materials like copper and aluminum, which have traditionally posed challenges for non-fiber technologies. A study conducted by MarketsandMarkets projects that the fiber laser market will reach $4.93 billion by 2026, driven by the growing demand for high-speed, high-precision manufacturing capabilities. This trend further emphasizes the critical role fiber laser technology plays in enhancing productivity and operational efficiency across various industrial sectors.

Efficiency Metrics: Speed and Precision in Modern Fiber Laser Cutting Applications

Fiber laser cutting technology has revolutionized modern manufacturing with its remarkable efficiency metrics, particularly in terms of speed and precision. This method leverages advanced laser technology to produce intricate cuts in various materials with minimal waste. The high-speed cutting capability allows manufacturers to streamline production processes, reducing cycle times and increasing overall output. Additionally, the precision offered by fiber lasers enables manufacturers to create complex geometries that were previously challenging to achieve, enhancing product quality and consistency.

Recent trends in laser technology also spotlight the innovation of startups that are pushing the boundaries of fiber laser applications. With over 680 startups emerging in this field, many are focusing on integrating artificial intelligence and automation to further enhance cutting capabilities. These advancements not only improve operational efficiency but also provide manufacturers with the ability to adapt to rapidly changing market demands. Moreover, the ongoing development of materials, such as black silicon, is set to enhance responsivity in photodetection applications, promoting advancements in sectors like defense and security, where near-infrared radiation measurement is crucial. This convergence of technology and manufacturing processes is poised to shape the future landscape of production.

Exploring the Benefits of Fiber Laser Cutters in Modern Manufacturing Techniques

| Application |

Material Type |

Cutting Speed (mm/min) |

Tolerance (mm) |

Power Consumption (kW) |

| Sheet Metal Cutting |

Mild Steel |

1200 |

0.1 |

2.5 |

| Tubular Cutting |

Aluminum |

900 |

0.05 |

3.0 |

| Precision Cutting |

Stainless Steel |

750 |

0.02 |

3.5 |

| Complex Shape Cutting |

Copper |

600 |

0.03 |

4.0 |

| High Volume Production |

Carbon Steel |

1300 |

0.1 |

2.8 |

Cost Analysis: Fiber Laser Cutters vs. Conventional Cutting Methods

When comparing fiber laser cutters to conventional cutting methods, cost analysis reveals significant advantages for manufacturers. Initially, the investment in fiber laser technology may seem higher due to the machinery's sophisticated components. However, the operating costs typically align favorably in the long run. Fiber lasers consume less electrical energy and require less maintenance than traditional cutting machines, which rely on more complex mechanical parts. This lower operational overhead, combined with their efficiency, allows for more precise and faster cutting, ultimately reducing labor costs and increasing productivity.

Moreover, fiber laser cutters can operate on a wider range of materials and thicknesses without the need for frequent tool changes. This versatility minimizes downtime, which is a critical cost factor in manufacturing. In comparative scenarios, the reduced kerf width of fiber lasers also leads to less material wastage, allowing companies to optimize their material usage and cut costs further. As manufacturers seek to enhance productivity while keeping expenses in check, the cost-effectiveness of fiber laser cutters becomes a compelling argument for their adoption over traditional cutting methods.

Exploring the Cost Benefits of Fiber Laser Cutters vs. Conventional Cutting Methods

This chart illustrates the cost per hour associated with fiber laser cutters compared to conventional cutting methods, highlighting significant savings when utilizing fiber laser technology in modern manufacturing practices.

Sustainability Benefits: Reducing Waste with Fiber Laser Technology in Production

Fiber laser technology is revolutionizing modern manufacturing techniques, particularly in terms of sustainability. One notable benefit is its ability to significantly reduce waste during production processes. According to a report by the Laser Institute of America, fiber laser cutters can achieve a material utilization rate of up to 90%, compared to 70-80% for traditional cutting methods. This increased efficiency means that manufacturers not only save on raw material costs but also contribute less to landfill waste, aligning with global initiatives for environmental conservation.

Moreover, the precision of fiber lasers minimizes kerf and allows for tighter tolerances, leading to reduced scrap material. A study published by Allied Market Research estimates that the global market for laser cutting technologies is expected to exceed $4 billion by 2026, driven in part by the demand for sustainable manufacturing practices. As more companies seek to enhance their green credentials and improve operational efficiencies, investing in fiber laser technology proves to be a strategic move that benefits both the bottom line and the environment.

Industry Adoption Rates: Trends in Fiber Laser Cutter Usage Across Manufacturing Sectors

The adoption of fiber laser cutters in modern manufacturing is witnessing significant growth across various sectors. The global fiber laser cutter market is projected to expand from

USD 2.16 billion in 2025, reaching an estimated

USD 3.35 billion by 2034, reflecting a compound annual growth rate (CAGR) of 5%.

This surge indicates an increasing reliance on fiber laser technology for precision cutting applications, driven by its efficiency and versatility in handling diverse materials.

Moreover, the broader fiber laser market is forecasted to exhibit even more robust growth, with expectations to jump from approximately

USD 6.87 billion in 2024 to

USD 17.55 billion by 2033, showcasing a CAGR of over 11.5%. This growth trend is reflective of the widespread acceptance of fiber lasers in sectors such as

AUTOMOTIVE, AEROSPACE, and ELECERNICS, where intricate designs and rapid production times are crucial. Additionally, the laser welding market is also on the rise, with projections indicating an increase from

USD 2.9 billion in 2025 to

USD 4.2 billion by 2035, at a CAGR of 3.7%. These trends underscore the pivotal role of fiber laser technology in advancing modern manufacturing techniques.