2026 Top Trends in Tube Laser Cutting Machines for Next Generation Manufacturing?

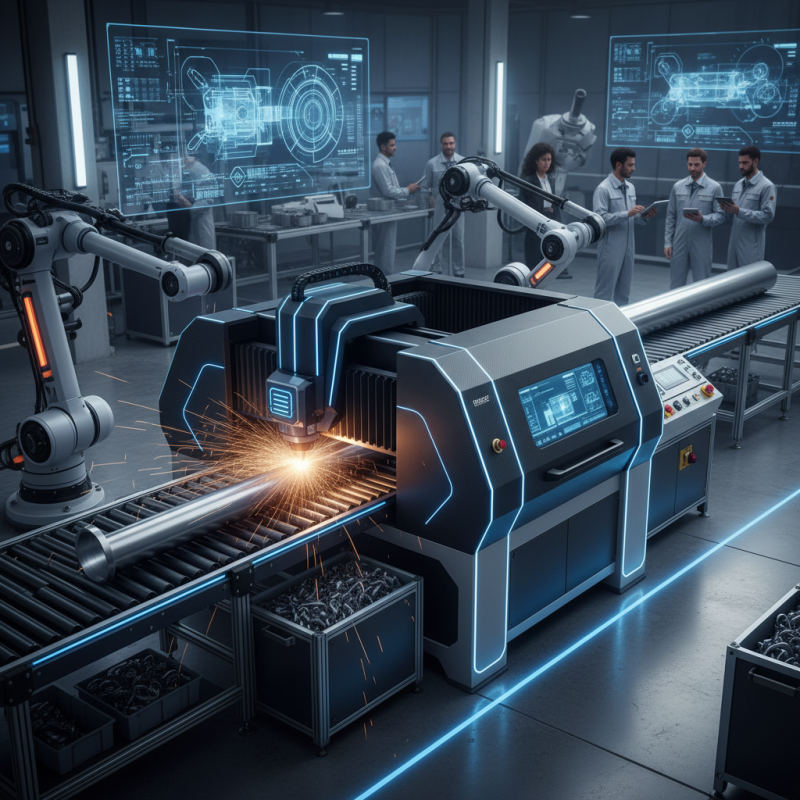

In the ever-evolving landscape of manufacturing, the tube laser cutting machine has become a game-changer. Industry expert John Smith notes, "The future of fabrication lies in precision and efficiency." As companies aim to enhance productivity, the demand for advanced cutting solutions grows. This trend shapes the competitive market.

The key developments in tube laser cutting machines are remarkable. They include automation, enhanced software, and improved cutting speeds. These changes not only streamline processes but also reduce waste. However, with advancements come challenges. Companies must adapt to new technologies and rethink their approaches.

Investing in tube laser cutting machines requires careful consideration. High costs can deter some businesses. Yet, the potential for increased output and lower operational costs is enticing. Companies must weigh the pros and cons. Ultimately, embracing innovation is crucial in staying relevant in the industry.

Future Innovations: The Rise of Automation in Tube Laser Cutting Machines

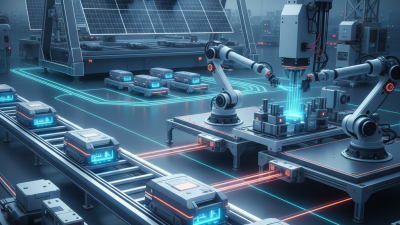

Automation is transforming tube laser cutting machines, enhancing efficiency and precision. The rise of smart technology is noteworthy. These machines now include sensors that monitor performance in real-time. This data can help predict maintenance needs, reducing downtime. Adopting this technology requires significant investment, which can be a barrier for some manufacturers.

Integration with AI is another trend. AI algorithms can optimize cutting paths and reduce material waste. However, implementing AI is not straightforward. Companies may struggle with the complexity of these systems. Additionally, there may be resistance from workers who fear job displacement.

Despite these challenges, the benefits are clear. Automated machines can operate longer hours without fatigue. They produce consistent quality, which is critical in precise industries. Embracing this trend might mean rethinking workforce roles and training programs. Manufacturers need to prepare for a future where adaptability is key.

Integration of AI and Machine Learning in Manufacturing Processes

The manufacturing landscape is undergoing a significant transformation. The integration of AI and machine learning in manufacturing processes has emerged as a game-changer. According to a recent report by McKinsey, companies that fully implement AI can expect to boost their productivity by up to 40%. This sharp increase highlights the capability of AI to optimize operations.

In the realm of tube laser cutting machines, AI facilitates real-time decision-making and predictive maintenance. Machines equipped with AI analyze data continuously. They assess performance, predict failures, and schedule maintenance before issues arise. A study published in Deloitte's Insights indicates that predictive maintenance can save manufacturers up to 12% in maintenance costs annually. However, not all companies are leveraging these technologies effectively.

Adopting AI requires a cultural shift within organizations. Employees must be trained to work alongside intelligent machines. A report from PwC notes that 37% of businesses lack a clear strategy for integrating AI. This gap can hinder potential growth and efficiency. Companies must reflect on their approach, ensuring that AI is not only an addition but a core component. The future of manufacturing lies in this synergy between human expertise and machine intelligence.

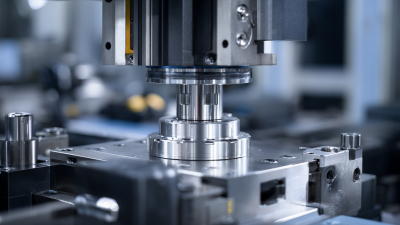

Advancements in Precision and Speed for Enhanced Cutting Performance

The landscape of manufacturing is evolving rapidly.

Tube laser cutting machines are at the forefront of this change.

Advances in precision and speed are reshaping how we approach metal fabrication.

Faster cutting speeds allow for increased productivity. However, with speed comes the challenge of maintaining accuracy.

Balancing both aspects is crucial for optimal results.

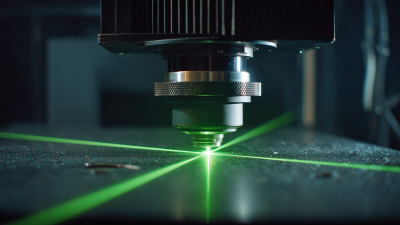

Recent developments feature innovative technologies that enhance cutting performance.

With higher wattage CO2 and fiber lasers, operators can execute intricate designs with ease.

These machines can achieve tighter tolerances, which was not feasible a decade ago.

But while these advancements are impressive, they require careful handling.

Misalignment or improper setup can lead to wasted materials and time.

As manufacturers embrace these changes, training becomes vital.

Skilled operators are essential to harness the full potential of advanced machinery.

Mistakes can be costly, underscoring the importance of continuous learning.

Embracing innovation should not overshadow the need for a knowledgeable workforce.

Striking a balance between speed and precision is an ongoing challenge in the industry.

The journey toward mastering these tools is just beginning.

Sustainable Manufacturing: Eco-friendly Practices in Tube Laser Cutting

In today's manufacturing landscape, sustainability is not just a trend; it's a necessity. Tube laser cutting machines play a pivotal role in this shift. They offer precision and efficiency, which helps minimize waste. This technology enables manufacturers to use less energy without sacrificing quality. Eco-friendly practices in tube laser processing can lead to significant reductions in carbon footprints.

Beyond energy efficiency, the materials used in manufacturing are also transforming. Many manufacturers are now opting for recyclable metals. This change is vital to reducing landfill waste. However, the transition isn’t always smooth. Companies may struggle to find reliable suppliers of eco-friendly materials. This inconsistency can hamper progress and require constant adjustments.

Moreover, while tube laser cutting is advanced, it isn’t infallible. Machine maintenance can sometimes be overlooked. Neglecting this can lead to increased energy consumption and waste. Companies must regularly assess their practices to ensure they align with sustainability goals. The journey towards sustainable manufacturing is complex, yet it offers vast potential for improvement.

2026 Trends in Tube Laser Cutting Machines

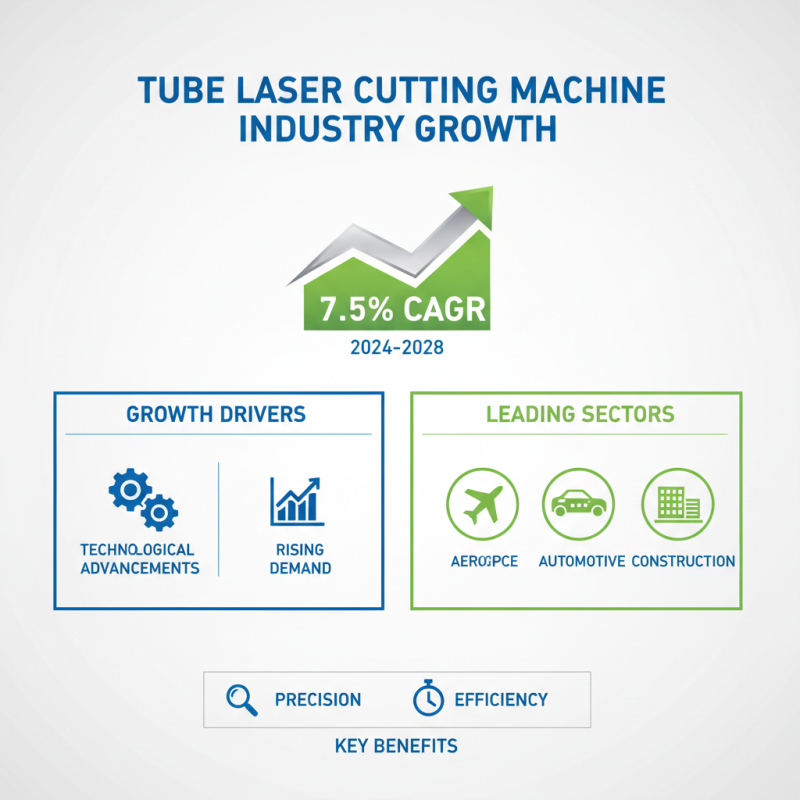

Market Trends: Forecasting Industry Growth and Technological Adoption

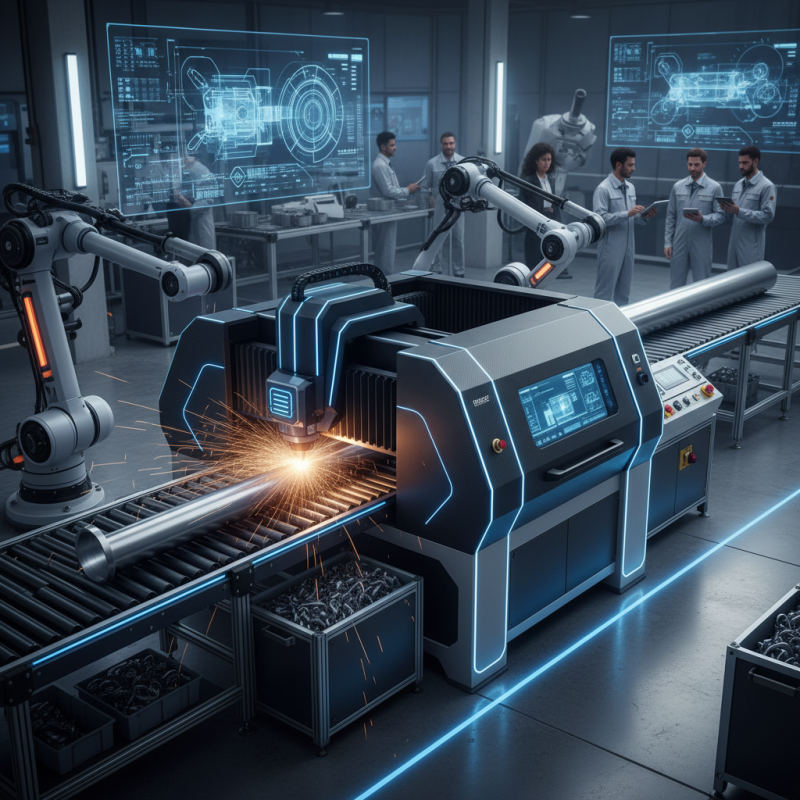

The tube laser cutting machine industry is poised for significant growth in the coming years. A recent report predicts a compound annual growth rate (CAGR) of 7.5% from 2024 to 2028. This expansion is driven by technological advancements and rising demand across various sectors. Aerospace, automotive, and construction industries are leading the charge. These sectors increasingly adopt laser cutting for its precision and efficiency.

Technological adoption is crucial to industry evolution. Advanced automation and smart integration are becoming standard. A study by an industry research firm indicates that over 50% of manufacturers are investing in automated solutions to enhance productivity. However, many operators struggle to keep pace with these developments. The need for skilled labor in operating advanced systems is a growing concern.

Despite the promising trends, challenges remain. Investment costs for modern machines can be substantial. Many small-to-medium enterprises find it hard to justify these expenses. Moreover, maintaining operational efficiencies often requires continuous training and development. It's essential to rethink current strategies to ensure long-term competitiveness in this evolving market.