2026 Top Linear Servo Motor Innovations and Applications Guide?

The development of linear servo motors is revolutionizing various industries. These motors provide precise control and high performance in many applications. According to a recent report by MarketsandMarkets, the global linear actuator market is expected to reach $8.1 billion by 2026, demonstrating a compound annual growth rate of 5.8%. This growth indicates a rising demand for linear servo motor technologies.

Companies across sectors, such as robotics and automation, are increasingly adopting these innovations. Linear servo motors enhance efficiency and accuracy, making them invaluable in manufacturing and material handling. Their ability to deliver rapid positioning and high speed contributes to better productivity. However, challenges remain in terms of integration with existing systems and cost considerations.

As the industry evolves, more research and development will be essential. Companies must focus on addressing these challenges while pushing the boundaries of linear servo motor capabilities. Innovations in this field could ultimately lead to groundbreaking applications that we have yet to imagine.

Overview of Linear Servo Motors and Their Importance

Linear servo motors play a crucial role in modern automation and robotics. They provide precise movement and control, essential for various applications. In manufacturing, these motors help optimize processes. They are often used in assembly lines, reducing downtime and increasing productivity. The accuracy of linear servo motors enhances the quality of finished products.

In healthcare, they assist in medical devices. For example, they enable precise movements in robotic surgeries. This application is vital for patient safety and improving recovery times. However, some challenges persist. The cost of linear servo motors can be a barrier for small manufacturers. Additionally, integration into existing systems can be complicated, requiring thoughtful planning.

Environmental concerns also arise. The production of components impacts sustainability. Efforts to use recyclable materials are ongoing, but not yet widespread. There is potential for innovation in energy efficiency. Rethinking these aspects can lead to advancements that align with global goals. As industries evolve, the importance of linear servo motors will only grow.

Key Innovations in Linear Servo Motor Technology for 2026

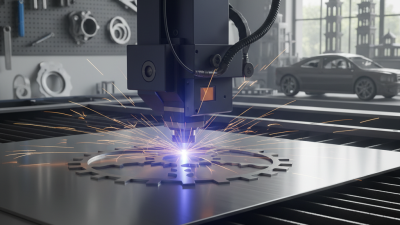

In 2026, innovative developments in linear servo motor technology are set to reshape automation. These motors will become more efficient and versatile. Advanced materials are being integrated, allowing for lighter, yet stronger components. The reduction in weight enhances speed and precision, vital for many applications. Engineers are experimenting with designs that minimize friction and energy loss.

User interface improvements are also noteworthy. Interactive controls empower users to optimize performance. These interfaces are intuitive, enabling quick adjustments during operations. However, while technology advances, challenges remain. Not all applications harness the potential of these innovations effectively. Some industries still rely on outdated systems. This gap highlights the need for ongoing education.

Moreover, the rise of AI in automation is influencing linear servo motors. AI can predict maintenance needs, enhancing reliability. Systems can learn from operation patterns, increasing efficiency. Still, there's the question of potential overdependence. If technology fails, legacy systems may lag behind. It's crucial to strike a balance between embracing innovation and maintaining fundamental skills.

Applications of Linear Servo Motors Across Various Industries

Linear servo motors are transforming various industries with their precision and efficiency. From robotics to manufacturing, these motors enable remarkable advancements. They provide accurate motion control, essential for tasks demanding high precision. In the automotive sector, linear servos facilitate assembly lines, improving production speed and quality. In medical equipment, they allow for precise positional control in devices like MRI machines.

**Tip:** When considering linear servo motors, assess your specific needs. Understand the size and power requirements for your application.

The aerospace industry also leverages linear servo motors. They enhance the performance of drones and aircraft systems. These motors contribute to improved reliability and lower maintenance costs. However, implementing linear servos is not without challenges. It’s vital to ensure proper integration with existing systems, which may require thorough testing and calibration.

**Tip:** Regularly review your motor specifications. Ensure they match your evolving technological needs.

In automation, these motors enable faster production cycles. They offer unmatched speed compared to traditional systems. There could be a learning curve for operators. Training is crucial to maximize their potential. Balancing performance and operator skill is key.

2026 Top Linear Servo Motor Innovations and Applications Guide

| Industry |

Application |

Key Innovations |

Advantages |

| Manufacturing |

Automated Assembly Lines |

High Precision Control |

Increased throughput and reduced waste |

| Medical |

Robotic Surgery |

Enhanced Motion Feedback |

Improved precision in delicate procedures |

| Aerospace |

Flight Control Systems |

Integration with Advanced Sensors |

Increased reliability and safety |

| Automotive |

Electric Vehicle Drive Systems |

Compact and Lightweight Designs |

Enhanced performance and efficiency |

| Robotics |

Collaborative Robots (Cobots) |

Improved Force Control |

Greater safety when working with humans |

Future Trends in Linear Servo Motors and Their Potential Impact

The advancements in linear servo motors are shaping the future of various industries. These motors are crucial for precision applications. With improved response times, machines can operate more efficiently. Many sectors, like robotics and automation, are beginning to adopt these innovations. The trend is clear: demand is rising.

However, there are challenges to consider. Integrating new technology often requires upgrades in existing systems. This can be costly and time-consuming. Not all companies are ready for such investments. Additionally, there is a learning curve. Staff need training to handle sophisticated machinery. Failure to address this can lead to operational issues.

As industries evolve, so do expectations. Users seek higher accuracy and reliability. Innovations in materials and design play a role here. Lightweight materials improve speed, while new designs reduce wear. Businesses must stay informed to keep pace. Overlooking these trends could mean falling behind competitors. The future of linear servo motors is bright, but it is not without obstacles.

Challenges and Opportunities in Linear Servo Motor Development

Linear servo motors are evolving rapidly. Their applications span robotics, manufacturing, and automation. However, challenges persist in development. Achieving precision while minimizing costs is difficult. Engineers often grapple with balancing performance and affordability. As technology advances, the demand for more efficient systems rises. Meeting these expectations is essential for success.

Tips: Consider exploring new materials. They can improve performance significantly.

Designing these motors requires creativity and engineering skill. Thermal management remains a concern. Efficient heat dissipation extends motor life. Yet, many designs overlook this vital aspect. It can lead to failures in critical applications.

Tips: Test prototypes rigorously. Early detection of flaws saves time and resources.

Market competition drives innovation. Companies must stay ahead of trends. Identifying emerging applications is crucial. Collaboration across industries can offer fresh perspectives. However, understanding market needs is not always straightforward. Regular feedback from end-users helps refine designs.

2026 Top Linear Servo Motor Innovations and Applications