2026 Top Industrial Laser Cutter Trends and Innovations?

The industrial laser cutter market is evolving rapidly, driven by advancements in technology and increasing demand for precision manufacturing. According to a recent report by MarketsandMarkets, the industrial laser cutter market is expected to reach $5.38 billion by 2026, growing at a CAGR of 6.8%. This growth reflects the industry's shift towards automation and enhanced productivity.

Expert John Smith, a leading authority in laser technology, stated, “Innovation in industrial laser cutters is reshaping how manufacturers operate.” As companies invest in cutting-edge laser systems, they enhance their efficiencies and reduce operational costs. Emerging trends include better beam quality and fiber laser technology, which are indispensable for high-precision cutting.

However, challenges remain. Many manufacturers are still transitioning from older systems to modern industrial laser cutters. This shift often leads to inefficiencies and skill gaps within the workforce. Addressing these issues is vital for companies to stay competitive in this dynamic landscape.

Emerging Technologies in Industrial Laser Cutting for 2026

Emerging technologies are shaping the future of industrial laser cutting. One significant trend is the integration of artificial intelligence. AI can optimize cutting processes in real-time, which improves efficiency. This technology helps reduce waste by predicting material behavior accurately. However, it may take time for all manufacturers to adopt AI fully.

Another exciting development is the advancement in fiber laser technology. These lasers offer higher energy efficiency and better performance on various materials. The ability to cut thicker materials without additional costs is remarkable. But, there's a need for proper training for operators to maximize the benefits of this technology.

Additionally, automation plays a crucial role in modern laser cutting. Automated systems can handle multiple tasks simultaneously, boosting production rates. However, reliance on automation can lead to challenges in quality control. If not monitored properly, it may result in inconsistencies in the final product. Embracing these transformative technologies will require companies to continually adapt and rethink their operational strategies.

2026 Top Industrial Laser Cutter Trends and Innovations

This chart illustrates the top industrial laser cutter trends and innovations expected for 2026, highlighting their impact score based on industry insights. The trends include automation, advancements in fiber lasers, cost reduction strategies, integration of hybrid technologies, and better software integration.

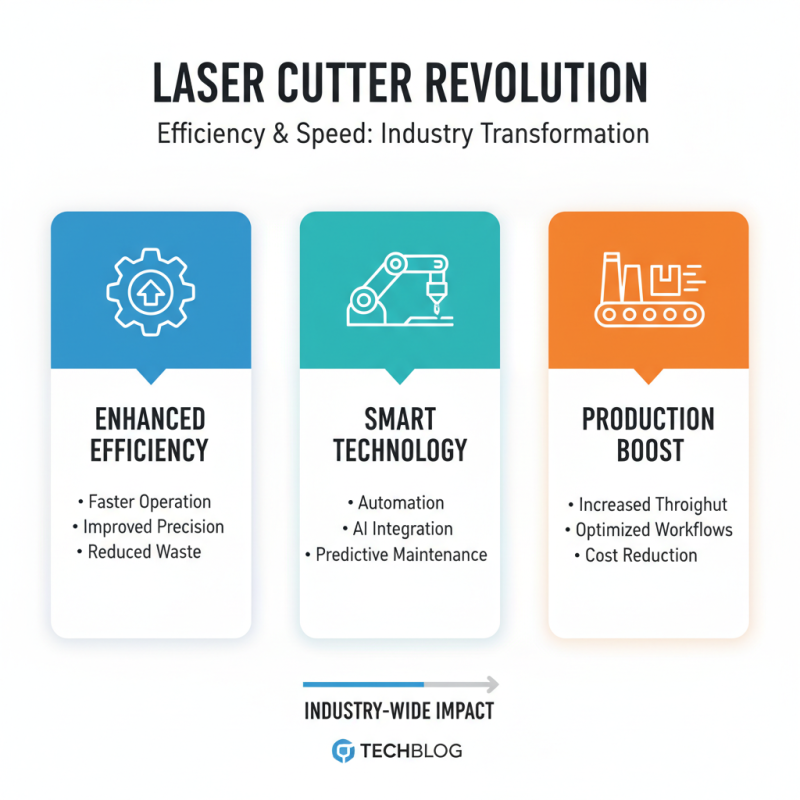

Advancements in Laser Cutter Efficiency and Speed

Advancements in laser cutter efficiency and speed are revolutionizing industries. Increased automation and smart technology integration are key trends. Modern laser cutters now operate at faster speeds without sacrificing precision. This boost in efficiency allows companies to enhance production workflows.

Investing in high-quality components can significantly improve cutter speed. However, not all facilities will optimize these upgrades. Some might overlook maintenance, leading to performance issues. Regular checks and calibration ensure that machines run smoothly. Ignoring these steps can create delays and waste.

Operators should stay informed about software updates. These often include features that enhance speed and accuracy. Yet, many facilities neglect this aspect. Training staff on new technologies can bridge this gap. They can then utilize the cutter’s full potential, resulting in better output. Leveraging these advancements requires attention to detail and commitment. Remember, even minor changes in processing can lead to substantial gains.

Sustainability Trends in Industrial Laser Cutting Practices

Sustainability in industrial laser cutting is gaining traction. Many companies are exploring ways to reduce waste. Traditional cutting methods generate scrap that often ends up in landfills. But with laser cutting, precision is key. This technology minimizes excess material, leading to less waste overall.

Energy efficiency is another focus. Laser systems are being designed to consume less power. This not only lowers operational costs but also reduces the carbon footprint. Furthermore, manufacturers are looking at reclaimed materials. Using recycled metal or plastic for cutting can close the loop. However, sourcing these materials can be challenging. Quality assurance still needs to be addressed.

Implementing sustainable practices is not without its issues. Some companies struggle with the initial investment for green technologies. Additionally, not all suppliers adhere to sustainable practices. This can create inconsistency in quality. Continuous improvement is essential in this rapidly evolving landscape. Balancing cost, efficiency, and environmental responsibility remains a work in progress for many.

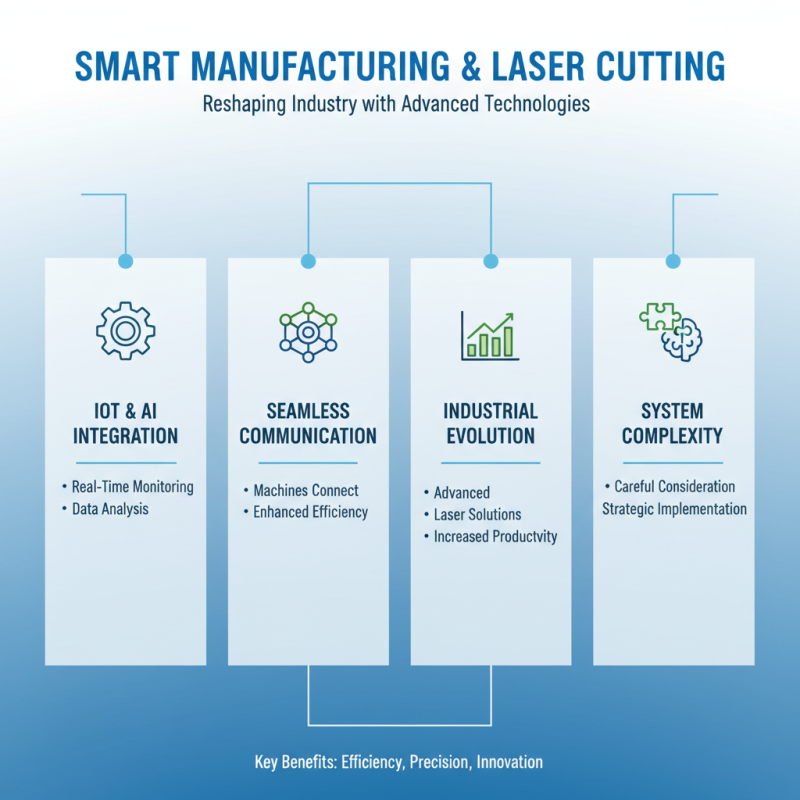

Integration of Smart Manufacturing with Laser Cutting Solutions

The integration of smart manufacturing with laser cutting solutions is reshaping the industrial landscape. Companies are now adopting advanced technologies like IoT and AI. These innovations enable real-time monitoring and data analysis. Machines communicate seamlessly, leading to enhanced efficiency. Yet, the complexities of these systems require careful consideration.

Not all manufacturers are ready to embrace this transition. Some struggle with outdated equipment. Others face challenges in workforce training. It's crucial to assess the current capabilities before integrating smart features. There can be hidden costs involved. Also, data security becomes a significant concern. As companies push forward, they must balance progress with caution.

Collaboration across industries is growing. Manufacturers are sharing insights and best practices. This creates a more robust ecosystem for laser cutting technologies. Even with the potential for huge gains, there are still many unknowns. Each step towards smart manufacturing necessitates reflection and strategic planning. Embracing innovation is exciting but requires a thoughtful approach.

Future Applications and Markets for Laser Cutting Technology

The future of laser cutting technology promises transformative applications across various industries. With projections indicating a growth rate of over 8% by 2026, the adoption of laser cutters in automotive, aerospace, and electronics will surge. Industry data has highlighted that these sectors aim to enhance precision and efficiency in their operations. For instance, the automotive industry is increasingly utilizing laser technology for lightweight structural components. Such components lead to improved fuel efficiency and reduced emissions.

As industries evolve, new markets are emerging. The medical field is exploring laser cutting for custom implants and surgical instruments. A recent report noted that personalized medical devices could see a 15% growth by 2025. This reflects a shift towards tailored healthcare solutions. However, challenges remain. Not all manufacturers are equipped to handle sophisticated technologies. Many still rely on outdated systems, which can slow progress.

Moreover, sustainability is becoming essential. Companies are under pressure to reduce waste. Laser cutting can minimize scrap material through precise cuts, but not everyone prioritizes this. The inconsistency in environmental practices poses a question mark for the industry's future. It’s a complicated dance between innovation and tradition, making the next few years pivotal for the laser cutting sector.

2026 Top Industrial Laser Cutter Trends and Innovations

| Trend/Innovation |

Description |

Future Applications |

Market Impact |

| Smart Automation Integration |

Incorporation of AI and machine learning for predictive maintenance and efficiency. |

Manufacturing, automotive, aerospace. |

Increased productivity and reduced downtime. |

| Multi-Material Cutting |

Ability to cut through various materials like metals, plastics, and ceramics on a single machine. |

Electronics, medical devices, and construction. |

Expansion of capabilities leading to new market opportunities. |

| Environmentally Friendly Processes |

Development of low-emission laser cutting technologies. |

Automotive, packaging, and textiles. |

Positive impact on regulatory compliance and consumer preference. |

| High-Speed Laser Cutting |

Advancements in optics and laser technology to achieve faster cutting times. |

Sheet metal fabrication, aerospace components. |

Higher throughput and reduced production costs. |

| Laser Cutter Portability |

Emergence of compact and mobile laser cutting systems. |

Construction and field repairs. |

Increased accessibility and versatility for users. |