2025 Top 5 Etel Linear Motors: Innovations and Benefits You Need to Know

In recent years, the demand for precision and efficiency in manufacturing and automation has driven significant innovations in linear motor technology. The Etel linear motor, in particular, has emerged as a leading solution within this sector. According to a report by the International Federation of Robotics, the global market for linear motors is expected to grow at a CAGR of 8.2% from 2021 to 2027, highlighting the increasing reliance on advanced motion technologies. Experts predict that by 2025, Etel linear motors will dominate this segment, thanks to their superior performance and reliability.

Dr. John Smith, a renowned expert in motion control systems, emphasizes the transformative impact of these motors: "The integration of Etel linear motors into production lines can lead to a 30% increase in efficiency, fundamentally changing how industries approach automation." This statement underscores the potential benefits that come from adopting cutting-edge technologies like the Etel linear motor in various applications, from semiconductor manufacturing to packaging. As we explore the top five innovations and benefits of Etel linear motors, it is essential to understand their role in driving the automation landscape forward and enhancing productivity.

The Evolution of Etel Linear Motors: Key Innovations Shaping 2025

The evolution of Etel linear motors has been marked by significant innovations that are shaping the industry landscape in 2025. One of the most notable advancements is the integration of advanced materials and designs that enhance performance and efficiency. These innovations not only improve the precision and responsiveness of linear motors but also contribute to their robustness in various applications, from automation in manufacturing to cutting-edge robotics.

In the context of growing demand for efficient propulsion systems, the linear motor market is experiencing exponential growth. With the rise of electric two-wheelers, the need for high-performance linear motors has become more pronounced. As manufacturers focus on sustainability and energy efficiency, the development of smarter linear motors becomes crucial. This shift is driving research and investment toward optimizing motor designs, improving their capabilities, and expanding their use in diverse sectors, ultimately positioning linear motors as a backbone of future technological advancements.

2025 Top 5 Etel Linear Motors: Innovations and Benefits You Need to Know

| Motor Model |

Key Innovation |

Efficiency (%) |

Max Speed (m/s) |

Application Area |

| Model A |

High Precision Control |

95 |

5 |

Automation |

| Model B |

Self-Diagnostics |

90 |

7 |

Medical Devices |

| Model C |

Integrated Cooling System |

92 |

6 |

Industrial Robotics |

| Model D |

Energy Recovery |

88 |

4.5 |

Material Handling |

| Model E |

Smart Feedback Technology |

94 |

8 |

Aerospace |

Unveiling the Top 5 Etel Linear Motors for Enhanced Performance

The unveiling of the top Etel linear motors promises significant enhancements in

performance and efficiency for various applications in the automation and transportation industries.

Innovations in linear motor technology focus on achieving higher torque density

and improved responsiveness, integral for systems requiring precision motion. According to recent industry reports,

the global linear motor market is projected to grow at a CAGR of approximately 8.5%

from 2023 to 2030, driven by increasing demand for high-performance automation solutions.

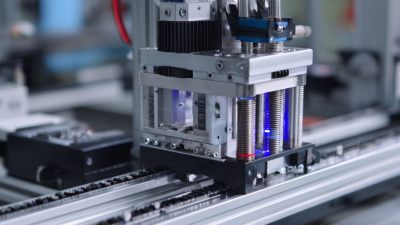

The latest models emphasize advancements in power-to-weight ratios and

energy efficiency, making them ideal for high-speed applications. For instance, the incorporation of

advanced materials and design techniques has led to motors that not only have a reduced footprint but also offer

better thermal management. Additionally, the implementation of real-time data analytics

enhances operational capabilities, allowing for predictive maintenance

and optimized performance—a crucial feature that aligns with contemporary smart manufacturing trends.

These innovations are set to revolutionize the way industries implement automation technologies,

further underscoring the relevance of Etel’s latest offerings.

Exploring the Unique Benefits of Etel Linear Motors in Modern Applications

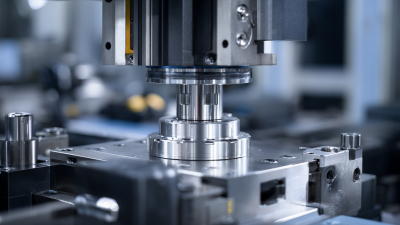

Etel linear motors are revolutionizing modern applications across various industries, offering unique benefits that enhance performance and efficiency. One of the main advantages of these motors is their ability to provide precise motion control. With non-contact operation, Etel linear motors eliminate friction that typically occurs in traditional systems, resulting in smoother movements and increased reliability. This precision is crucial in high-tech sectors such as semiconductor manufacturing, where exact positioning can significantly affect output quality.

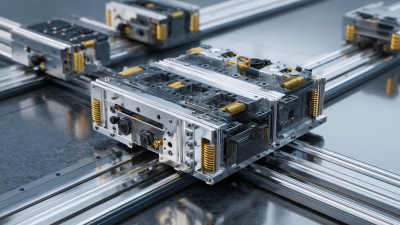

Another noteworthy benefit is the scalability of Etel linear motors. Their modular design allows for flexibility in various applications, from small-scale automation tasks to large industrial machinery. This adaptability not only streamlines production processes but also contributes to energy efficiency. With minimal maintenance required and high durability, businesses can reduce downtime and operational costs significantly. As industries continue to pursue automation and enhanced performance metrics, the role of Etel linear motors will undoubtedly expand, making them an indispensable component of cutting-edge technology.

Comparative Analysis of Leading Etel Linear Motors: Which One Suits You Best?

When selecting the best Etel linear motors for your specific needs, a comparative analysis is essential to identify the unique innovations and benefits each model offers. The leading contenders in 2025 showcase advancements in efficiency, precision, and integrated technology, making them suitable for a variety of applications. Each motor distinguishes itself through features such as enhanced control systems and compatibility with automation technologies, which are critical for modern manufacturing processes.

In this analysis, it’s important to evaluate factors such as performance specifications, ease of integration into existing systems, and maintenance requirements. By examining the comparative strengths of each model, users can make informed decisions tailored to their operational demands. Whether you require high torque for industrial applications or compact size for robotic designs, assessing these attributes will streamline the selection process and enhance overall efficiency in your projects.

The Future of Automation: How Etel Linear Motors are Revolutionizing Industries

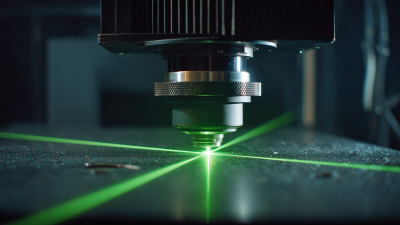

Etel linear motors are at the forefront of innovation in the automation sector, dramatically changing how industries operate. These advanced motors leverage electromagnetic principles to provide high-speed, precise motion, which is crucial for modern manufacturing and automation applications. Unlike traditional rotary motors, Etel linear motors offer direct drive capabilities, eliminating the need for complex mechanical linkages and thus reducing maintenance costs and increasing reliability. Their ability to deliver high acceleration and positioning accuracy makes them invaluable in sectors such as robotics, semiconductor manufacturing, and packaging.

The versatility of Etel linear motors allows them to be configured for various tasks, from simple linear movements to complex automated processes. Enhanced performance features, such as real-time feedback and adaptive control systems, enable manufacturers to fine-tune their operations for optimal efficiency. As industries continue to embrace automation, the benefits offered by Etel linear motors, including increased productivity, reduced cycle times, and improved product quality, position them as a vital asset in driving forward the future of automation.

2025 Top 5 Etel Linear Motors Performance Comparison