Top 2025 Steel Laser Cutting Machine Innovations and Industry Trends

In the ever-evolving landscape of manufacturing technology, the steel laser cutting machine stands out as a pivotal innovation facilitating precision and efficiency in metal processing. Industry expert Dr. Emily Chen, a leader in laser technology research, emphasizes the transformative impact of these machines when she states, "The advancements in steel laser cutting technology not only enhance productivity but also open new avenues for design and application in various industries." As we look towards 2025, it is essential to understand the innovations shaping this essential tool and the trends driving its integration in various sectors.

The advancements in fiber laser technology, automation, and smart manufacturing are redefining the capabilities of steel laser cutting machines. With increasing demands for high-quality outputs and faster turnaround times, manufacturers are leveraging these innovations to stay competitive. Furthermore, the trend towards sustainable practices in manufacturing has led to highly efficient energy consumption and reduced material waste, reflecting a broader commitment to environmental responsibility.

As we delve into the latest innovations and industry trends surrounding steel laser cutting machines, it becomes clear that these technologies are not just tools but are central to the future of manufacturing excellence. By understanding these developments, businesses can better position themselves to harness the full potential of cutting-edge laser technology.

Emerging Technologies in Steel Laser Cutting Machines for 2025

As we move towards 2025, the landscape of steel laser cutting machines is poised for transformative change driven by emerging technologies. The integration of Artificial Intelligence (AI) and machine learning is expected to revolutionize the operational efficiency of laser cutting systems. According to a report from the International Laser Manufacturing Network, over 60% of manufacturers are investing in smart technology to enhance predictive maintenance and reduce downtime. This proactive approach not only minimizes operational costs but also boosts production capabilities by increasing workflow efficiency.

Additionally, advancements in fiber laser technology are set to improve cutting speeds and precision significantly. Research indicates that fiber lasers can increase cutting speeds by up to 30% compared to traditional CO2 lasers, which translates to better productivity and lower energy consumption. Sustainability is also becoming a crucial consideration; the shift towards eco-friendly solutions and the development of machines that offer higher energy efficiency and reduced waste will align steel manufacturing practices with global environmental standards. In a market valued at approximately $7 billion in 2023, these innovations signal a commitment to not only enhancing performance but also addressing high-demand concerns of sustainability within the industry.

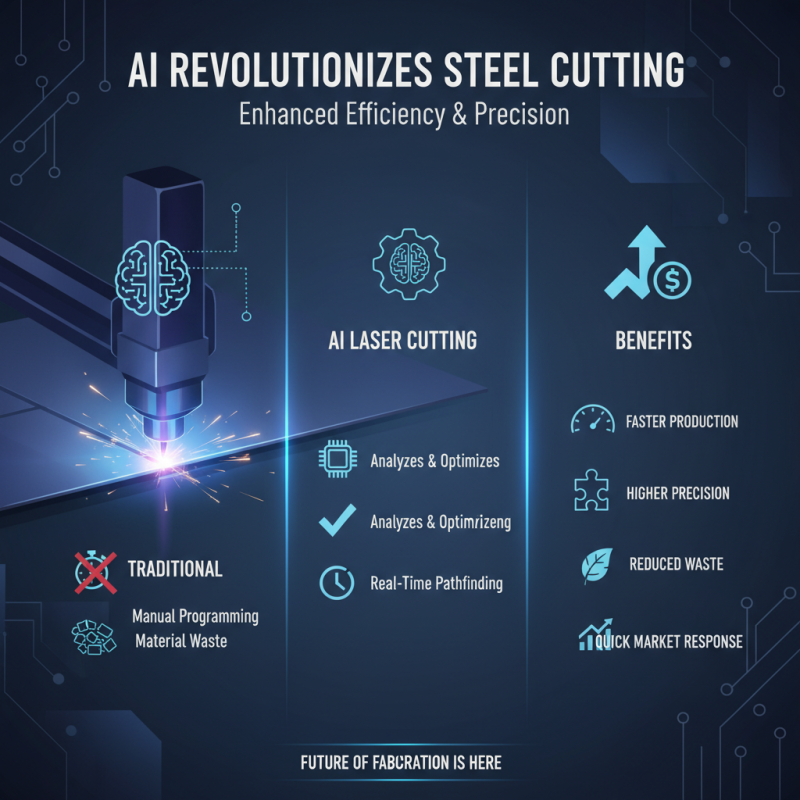

Advancements in Laser Cutting Efficiency and Precision

In recent years, advancements in laser cutting technology have significantly enhanced both efficiency and precision, revolutionizing the steel fabrication industry. One of the most notable innovations is the integration of artificial intelligence into laser cutting systems. AI algorithms can analyze materials and optimize cutting paths in real-time, resulting in significant reductions in cutting time and material waste. This not only improves productivity but also ensures that projects are completed with maximum efficiency, allowing companies to respond swiftly to market demands.

Moreover, the development of high-power fiber lasers has set new standards for precision in laser cutting. These lasers can achieve finer cuts with smoother edges, enabling manufacturers to produce intricate designs without compromising quality. Coupled with improved focus control technologies, the accuracy of cuts has reached unprecedented levels, catering to industries that require meticulous detail in design and fabrication. As these technologies continue to evolve, the potential for automation and integration into smart manufacturing systems grows, paving the way for a future where laser cutting is not only faster but also more precise than ever before.

Integration of Automation and AI in Steel Processing

The integration of automation and artificial intelligence (AI) in steel processing is revolutionizing the industry, setting the stage for significant advancements in efficiency and precision. According to a report by Allied Market Research, the global steel automation market is projected to reach $7.8 billion by 2025, illustrating a strong shift toward automated solutions. The increasing demand for high-quality steel products, coupled with the need for reduced operational costs, propels the adoption of advanced technologies, particularly AI and machine learning algorithms that optimize cutting processes in laser cutting machines.

AI-driven systems not only enhance the accuracy of steel cutting but also facilitate predictive maintenance, minimizing downtime associated with equipment failures. A recent study published by ResearchAndMarkets indicates that AI can improve operational efficiency by up to 30% in manufacturing processes. This transformative capability allows companies to respond rapidly to market changes and meet the rising demand for customized steel products. Furthermore, the automation of steel processing reduces labor costs significantly, encouraging more enterprises to transition from traditional methods to smart manufacturing solutions. As innovations in AI continue to progress, the industry is poised for a future characterized by unprecedented quality and productivity levels.

Top 2025 Steel Laser Cutting Machine Innovations and Industry Trends

| Innovation/Trend |

Description |

Impact |

Projected Adoption Rate |

| AI-Driven Quality Control |

Integration of machine learning algorithms to monitor and ensure cutting quality. |

Reduces waste and improves efficiency. |

75% |

| Automation in Material Handling |

Use of automated systems for loading and unloading materials. |

Enhances operational safety and speed. |

60% |

| Adaptive Cutting Technology |

Systems that adjust cutting speeds based on material thickness in real time. |

Improves precision and reduces cycle times. |

50% |

| Remote Monitoring and Diagnostics |

Utilizing IoT technology for real-time machine performance analysis. |

Proactive maintenance and reduced downtime. |

70% |

| Enhanced User Interfaces |

Development of intuitive control panels with touch screens and visual aids. |

Streamlines operator training and usability. |

80% |

Sustainability Trends Impacting the Steel Laser Cutting Industry

The steel laser cutting industry is undergoing significant transformation, driven by sustainability trends that are reshaping manufacturing practices. According to a recent report by Research and Markets, the global market for laser cutting machines is expected to reach $4.5 billion by 2025, with an increasing emphasis on eco-friendly technologies. This shift arises from the growing awareness of environmental issues, including carbon emissions and resource depletion, pushing manufacturers to adopt practices that minimize their ecological impact.

Innovations in steel laser cutting technology are focusing on energy efficiency and waste reduction. For instance, advancements in fiber laser systems deliver cutting processes that consume up to 50% less energy compared to traditional CO2 lasers. Moreover, the integration of automated material handling systems allows manufacturers to optimize material usage, reducing scrap rates significantly. A study by the International Energy Agency suggests that improving operational efficiency in steel production could reduce emissions by as much as 30% by 2030, underscoring the importance of adopting sustainable practices in laser cutting applications.

As companies strive to meet regulatory requirements and embrace corporate social responsibility, the incorporation of sustainability into their operational strategies becomes not only advantageous but essential. The push for an eco-conscious approach is also reflected in consumer preferences, with 64% of global consumers expressing a preference for sustainable brands, according to Nielsen. This evolving landscape presents both challenges and opportunities for the steel laser cutting industry as it adapts to meet new sustainability standards while promoting innovation and efficiency.

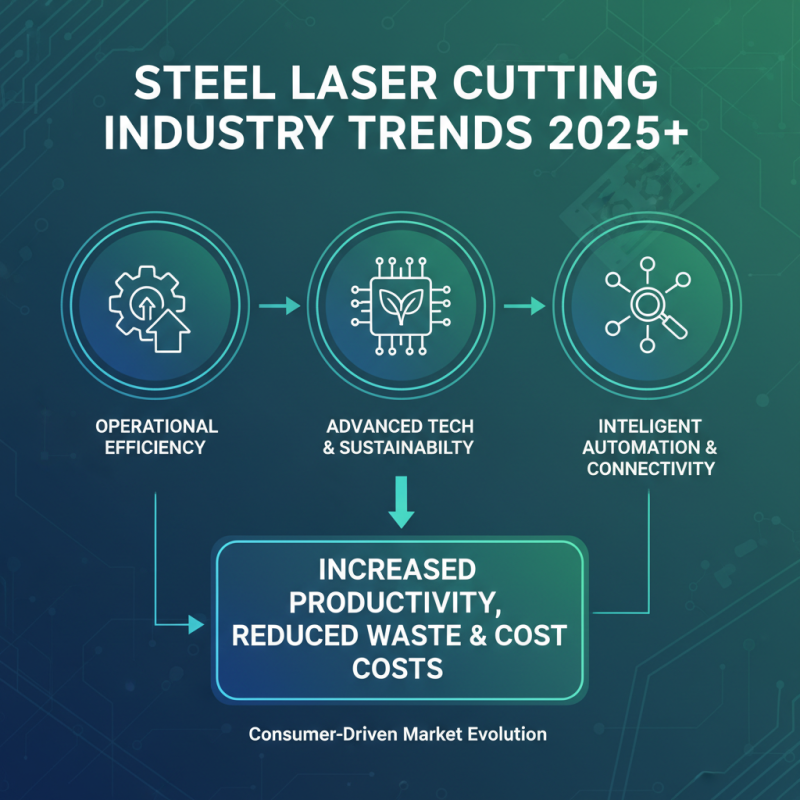

Future Market Projections and Consumer Demands in Laser Cutting Solutions

As the landscape of the steel laser cutting industry evolves, consumer demands are increasingly shaping market projections for 2025 and beyond. Companies are looking for solutions that not only enhance operational efficiency but also integrate advanced technology and sustainability. There is a growing emphasis on user-friendly interfaces, intelligent automation, and machine connectivity, allowing for real-time monitoring and data analytics. This shift underscores the industry's commitment to increasing productivity while minimizing waste and operational costs.

Moreover, environmental considerations are becoming a priority for consumers, driving the demand for machines that reduce energy consumption and emissions. As industries seek to comply with stricter regulations and corporate sustainability goals, the trend towards eco-friendly laser cutting solutions is likely to take center stage. Innovations that incorporate green technologies will not only attract environmentally conscious clients but also enhance a manufacturer's competitive edge in a crowded marketplace. Ultimately, the convergence of advanced technology and sustainability will define the future of steel laser cutting solutions, catering to the evolving needs of consumers and paving the way for a more responsible industrial landscape.