2025 Guide: How to Choose a Metal Laser Cutting Machine for Home Use

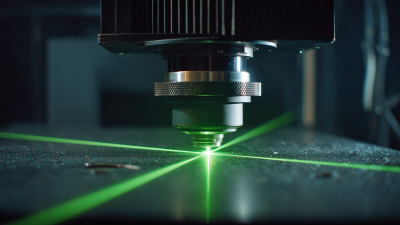

As the demand for precision cutting increases, many hobbyists and small businesses are turning to advanced technology for their metalworking needs. It is projected that the global market for laser cutting machines will reach approximately $5 billion by 2025, according to a report by Grand View Research. This indicates a significant growth opportunity for those interested in using a metal laser cutting machine for home projects. With features including speed, accuracy, and versatility, these machines are now more accessible than ever.

Dr. Emily Johnson, a leading expert in the field of laser technology, emphasizes, "A metal laser cutting machine for home use not only enhances creativity but also streamlines many processes that were traditionally labor-intensive." This statement highlights the transformative impact that these machines can have on DIY manufacturing and prototyping tasks. As potential users consider their options, they must weigh factors such as machine specifications, user-friendliness, and safety features to ensure they select a device that meets their specific needs while maximizing efficiency.

In summary, choosing the right metal laser cutting machine for home use is essential for those looking to elevate their metalworking capabilities. With the proper knowledge and guidance, anyone can find a solution that not only fits their space but also unleashes their creative potential in the burgeoning field of home-based fabrication.

Considerations for Metal Laser Cutting Machines for Home Use

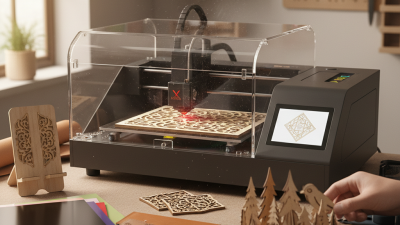

When selecting a metal laser cutting machine for home use, there are several key considerations to ensure that you invest in a tool that meets your needs and capabilities. First, assess the type of metal you plan to cut, as different machines have varying capabilities when it comes to thickness and material type. Additionally, consider the size and weight of the machine in relation to your workspace. Home environments often have limited space, so opting for a compact model can enhance convenience and usability.

Another crucial factor is the ease of use and maintenance. Look for machines that offer intuitive controls and user-friendly interfaces, especially if you're a beginner. Machines with built-in safety features and low maintenance requirements can provide peace of mind and a better user experience. Moreover, evaluate the availability of customer support and resources such as tutorials or manuals, as these can be invaluable when troubleshooting or learning to operate your new machinery effectively.

2025 Guide: Metal Laser Cutting Machine Features for Home Use

Key Features to Look for in a Metal Laser Cutting Machine

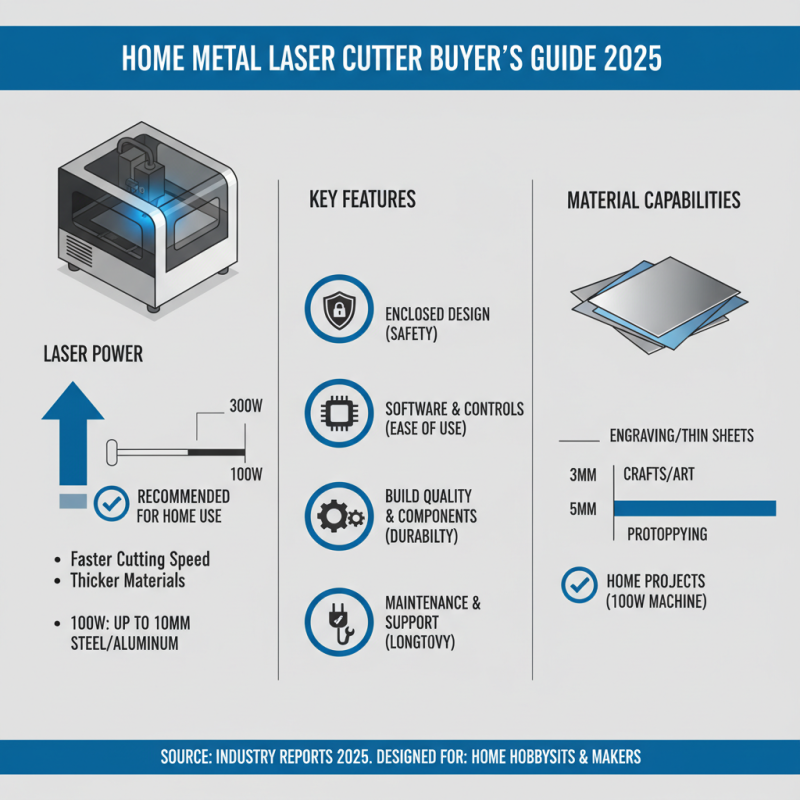

When selecting a metal laser cutting machine for home use in 2025, it's essential to consider several key features that can significantly impact performance and user experience. One of the most critical elements is the power output of the laser. Machines typically range from 40W to 300W, with higher wattage providing faster cutting speeds and the ability to process thicker materials. According to industry reports, machines with 100W power can effectively cut through materials up to 10mm thick, making them suitable for a variety of home projects.

Another important feature is the type of laser used, typically either CO2 or fiber lasers. CO2 lasers are versatile and can cut non-metal materials in addition to metal, while fiber lasers excel in cutting reflective metals and are generally more efficient. Research by the Laser Institute of America indicates that fiber lasers are up to three times faster than CO2 lasers, which may be a decisive parameter for home users seeking quick turnaround times for their projects.

Tips: When choosing a machine, examine the cutter's compatibility with different software programs. Many models now integrate seamlessly with popular design software, making it easier to bring your creative ideas to life. Additionally, consider the footprint and weight of the machine, especially if workspace is limited. A compact and portable model can offer flexibility and convenience for home usage without sacrificing performance.

Safety Standards and Regulations for Home Metal Cutting Equipment

When considering a metal laser cutting machine for home use, adherence to safety standards and regulations is paramount. The Occupational Safety and Health Administration (OSHA) outlines key safety measures to prevent accidents and injuries, highlighting the importance of protective equipment, proper ventilation, and machine safeguards. Additionally, according to a report by the American National Standards Institute (ANSI), machines should meet specific design criteria to mitigate risks associated with high-powered lasers, including beam containment and user safety interlocks.

It’s crucial for users to familiarize themselves with the International Electrotechnical Commission (IEC) standards, which detail requirements for laser safety classifications. For instance, a Class 1 laser system is considered safe under all conditions of normal use, whereas a Class 4 laser can cause skin burns and major eye damage, necessitating stringent safety protocols. Reports indicate that adherence to these safety standards not only ensures user safety but also enhances machine longevity and efficiency. The market underscores this need, with a notable increase in devices designed with built-in safety features, contributing to a burgeoning demand for compliant home metal cutting equipment.

2025 Guide: How to Choose a Metal Laser Cutting Machine for Home Use

| Feature |

Details |

| Cutting Thickness |

Up to 10 mm for mild steel, 5 mm for stainless steel |

| Power Consumption |

500W - 1500W |

| Cooling System |

Water-cooled and air-cooled options available |

| Safety Standards |

Complies with OSHA and ANSI safety regulations |

| Operating Environment |

Suitable for indoor use, must have proper ventilation |

| Software Compatibility |

Compatible with popular CAD software |

| Size and Weight |

Average weight of 50-150 kg, compact designs available |

| Warranty |

1 to 3 years depending on manufacturer |

Cost Analysis: Budgeting for a Metal Laser Cutting Machine

When budgeting for a metal laser cutting machine for home use, it's essential to take a comprehensive approach, considering not just the initial purchase price but other potential costs associated with operation and maintenance. Prices for metal laser cutters can vary widely depending on their specifications, capabilities, and brand reputation. Typically, you can expect to invest anywhere from a few hundred to several thousand dollars. Additionally, consider expenses such as ventilation systems, safety equipment, and software, which may significantly contribute to your overall budget.

Tips for effective budgeting include creating a checklist of essential features you need in a laser cutter and prioritizing them based on your specific projects. Research ongoing maintenance costs and potential repair expenses, as these can add up over time. It's also wise to seek out user reviews and testimonials to gauge the longevity of different models, helping ensure your investment lasts.

Finally, don't overlook the importance of operational costs. Calculate the price of materials you'll frequently use, as well as electricity and any additional tooling required for your projects. Having a clear picture of both upfront and recurring costs will help you make an informed decision that suits your financial situation and project needs.

Maintaining Efficiency: Best Practices for Home Laser Cutting Setup

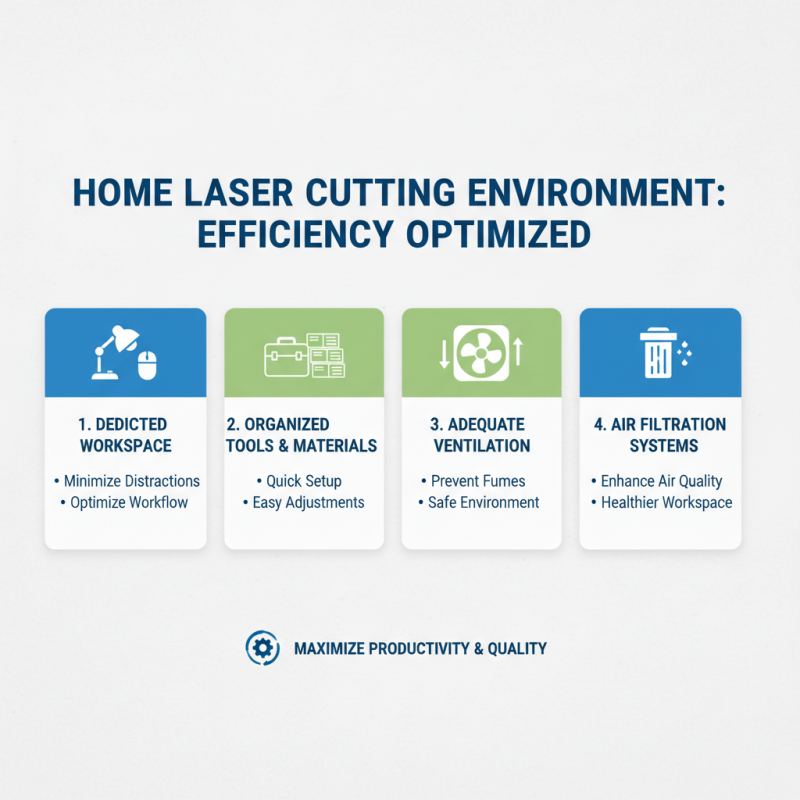

When setting up a home laser cutting environment, maintaining efficiency is paramount to maximizing productivity and achieving high-quality results. First, it is essential to create a dedicated workspace that minimizes distractions and optimizes workflow. Keeping tools and materials organized will help streamline the cutting processes, allowing for quick setup and adjustments during projects. Adequate ventilation is also crucial, as it prevents the buildup of fumes and ensures a safe working environment. Using exhaust systems or air filters can significantly enhance air quality, contributing to a healthier workspace.

Additionally, understanding the technical aspects of the laser cutting machine is vital for achieving the best results. Regular maintenance checks, such as cleaning lenses and mirrors, can enhance cutting precision and prolong the life of the equipment. It is also recommended to conduct test cuts on scrap materials to fine-tune settings before moving on to more valuable workpieces. Familiarity with software used for designing cuts will enhance efficiency, allowing users to maximize their machine's capabilities. By following these best practices, home users can create an effective and efficient setup for metal laser cutting that meets their project needs.