2025 Top CNC Laser Cutter Trends and Buyer Guide for Every Industry

As we approach 2025, the landscape of manufacturing continues to evolve, significantly influenced by advancements in technology. Among these innovations, the CNC laser cutter stands out as a pivotal tool that is reshaping various industries. This guide aims to delve into the top trends surrounding CNC laser cutters, providing valuable insights for prospective buyers across multiple sectors.

With the rise of automation and precision in manufacturing processes, the CNC laser cutter offers unparalleled accuracy and efficiency, making it an essential asset for businesses aiming to enhance their production capabilities. The ongoing improvements in laser technology and software integration will not only heighten operational effectiveness but also pave the way for new applications in diverse fields, including automotive, aerospace, and textiles.

As we explore the key trends and considerations for investing in a CNC laser cutter, it is crucial for buyers to understand the specific needs of their industry. This comprehensive overview will equip stakeholders with the knowledge necessary to make informed decisions, ensuring that they remain competitive in a rapidly changing market.

Emerging Trends in CNC Laser Cutting Technology for 2025

The CNC laser cutting technology is poised for significant advancements by 2025, reflecting a robust market outlook characterized by growing demand across various industries. With the global market projected to expand from $6.85 billion in 2025 to $14.14 billion by 2032 at a compound annual growth rate (CAGR) of 10.9%, manufacturers are increasingly focusing on innovative solutions that enhance efficiency and precision. Key trends include the integration of artificial intelligence and machine learning to optimize cutting processes, as well as the development of more versatile and compact laser systems catering to specific industrial needs.

Additionally, the market for laser cutting controllers is set to experience substantial growth, expected to surge from $438 billion in 2025 to $28.11 trillion by 2033, driven by a stable CAGR of 5.7%. This growth is largely attributed to advancements in controller technology, which improve the coordination between laser systems and manufacturing software. The emergence of automated laser cutting solutions is enabling quicker turnaround times while minimizing waste, positioning CNC laser cutting as an invaluable asset in modern production environments. As these technologies evolve, buyers will need to stay informed about the latest innovations to maximize their operational capabilities.

2025 CNC Laser Cutter Trends: Market Growth by Industry

Key Features to Look for in CNC Laser Cutters

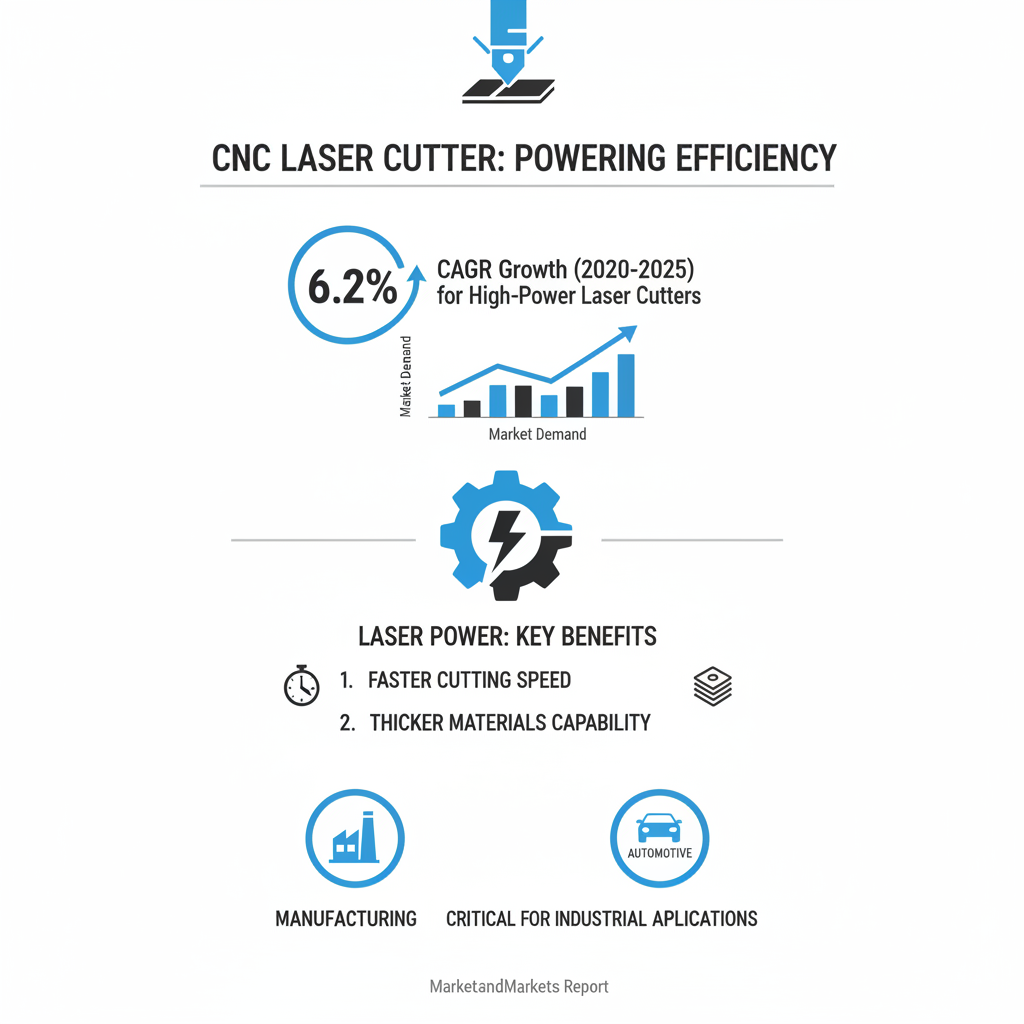

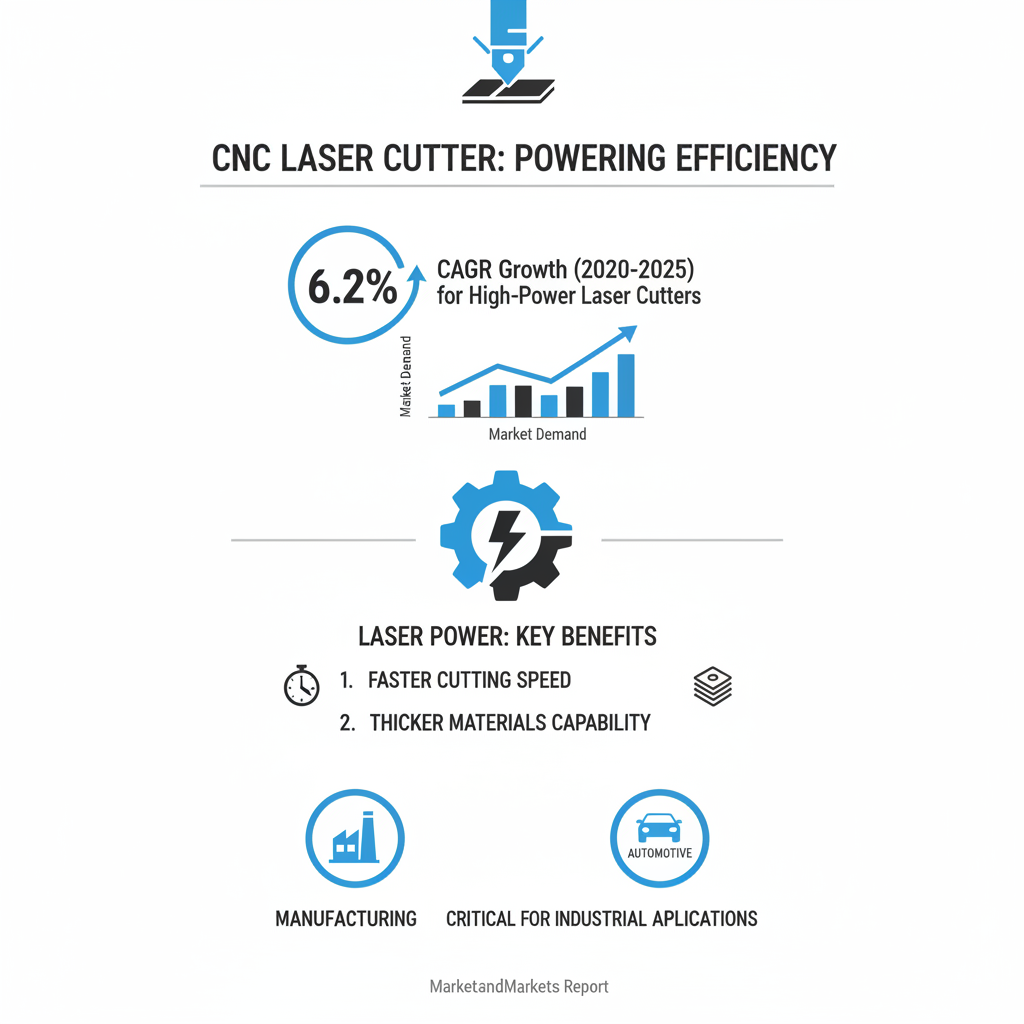

When considering a CNC laser cutter, it's crucial to focus on key features that can significantly impact operational efficiency and output quality. One of the most critical aspects is the laser power. According to a report by MarketsandMarkets, the demand for high-power laser cutters is expected to grow at a CAGR of around 6.2% from 2020 to 2025. Higher wattage allows for faster cutting speeds and the ability to work with thicker materials, making it a necessary specification for industries such as manufacturing and automotive.

Additionally, precision and repeatability are vital metrics to consider. High-quality CNC laser cutters are designed to provide consistent results, reducing material waste and refining production processes. Research from Grand View Research highlights that emerging technologies, such as fiber lasers, offer enhanced cutting precision with tolerances as tight as ±0.002 inches. Therefore, buyers must prioritize tools equipped with advanced optics and robust control systems that ensure precise cut profiles, ultimately driving better accuracy in final products across sectors like aerospace and signage.

Industry-Specific Applications of CNC Laser Cutters in 2025

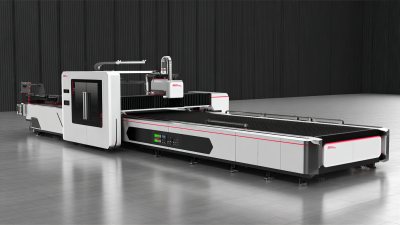

As the CNC laser cutter market continues to evolve, industry-specific applications are becoming increasingly prominent. In 2025, businesses across various sectors will leverage cutting-edge technologies like fiber lasers, CO2 lasers, and solid-state lasers to enhance their operational efficiency. The growth of the market is not only driven by advancements in laser technology but also by the rising demand for precision cutting in industries including automotive, aerospace, and electronics.

The COVID-19 pandemic has further catalyzed the need for automation and advanced manufacturing solutions. Companies are now focusing on applications such as cutting and drilling, welding, marking and engraving, and stamping, which are tailored to meet the demands of specific industries. For instance, the automotive sector is expected to witness a surge in the use of CNC laser cutters for creating intricate parts with minimal waste, while the electronics industry may utilize these machines for precise component fabrication.

As businesses adapt to post-pandemic realities, investing in specialized laser cutting solutions will be crucial for maintaining competitiveness and meeting customer expectations.

Cost Considerations and Budgeting for CNC Laser Cutter Purchases

When considering the purchase of a CNC laser cutter in 2025, understanding cost implications is crucial for businesses across various sectors.

According to a report by Grand View Research, the global CNC laser cutting machine market is projected to reach $5.69 billion by 2025, reflecting a compound annual growth rate (CAGR) of 7.8%. This growth emphasizes the increasing demand for precision engineering in industries such as automotive, aerospace, and manufacturing, where efficiency and accuracy are paramount.

Budgeting for a CNC laser cutter involves more than just the initial acquisition cost. Industry estimates suggest that operational expenses, including maintenance, energy consumption, and material costs, can significantly influence the total cost of ownership (TCO). For example, a high-quality CNC laser cutter may range from $60,000 to over $300,000, with additional yearly operational costs reaching upwards of 25% of the purchase price. Thus, it is vital for buyers to evaluate not just the upfront costs but also the long-term financial commitments, ensuring that they allocate adequate resources for training, software, and ongoing support to maximize their investment over time.

Maintenance and Support for CNC Laser Cutters: Best Practices

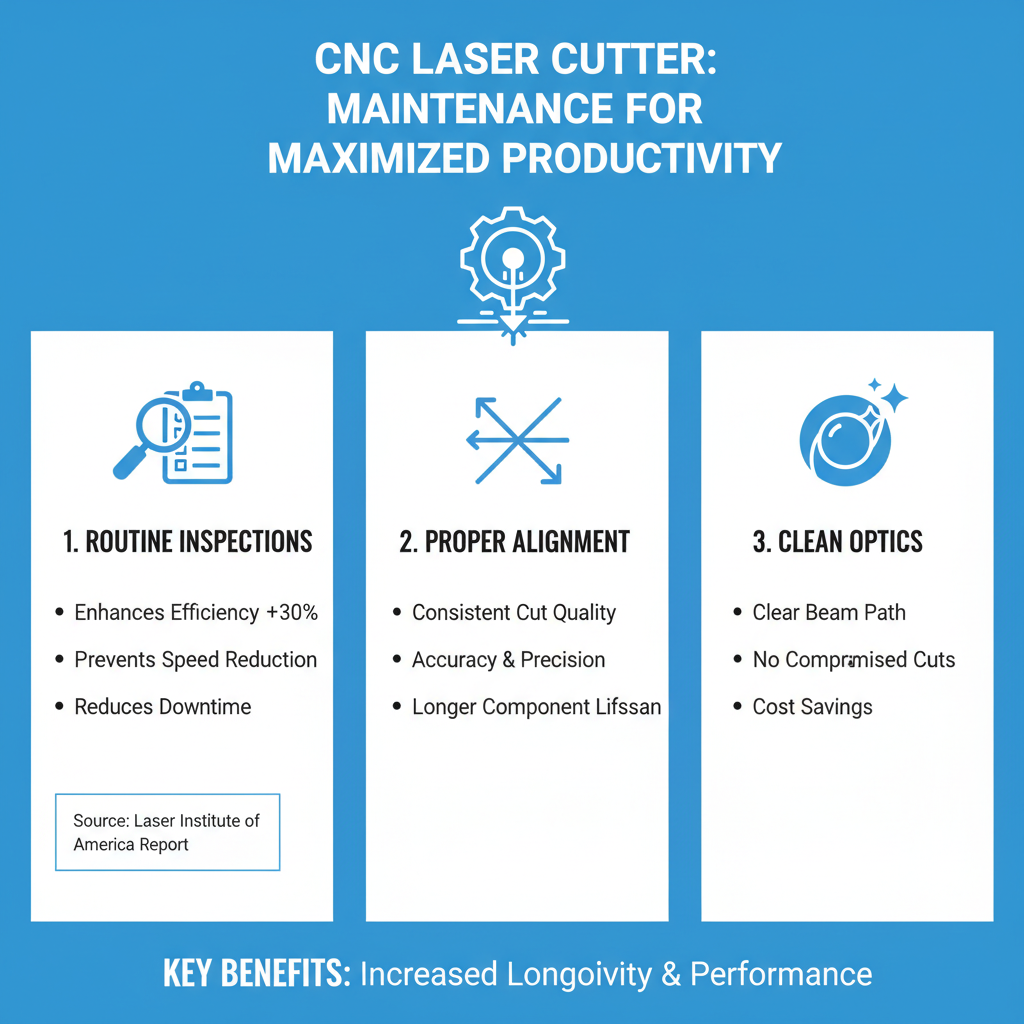

When investing in CNC laser cutters, understanding the maintenance and support aspects is crucial for maximizing productivity and longevity. A recent report from the Laser Institute of America emphasizes that routine maintenance can enhance a laser cutter's efficiency by up to 30%. Regular inspections, proper alignment, and clean optics prevent common issues such as reduced cutting speed and compromised cut quality, ultimately leading to significant cost savings and reduced downtime.

Best practices in maintenance include establishing a detailed schedule that incorporates daily, weekly, and monthly tasks. According to industry experts, regular training for operators on proper usage and care techniques can also reduce the likelihood of human error, which accounts for approximately 20% of machine failures. Furthermore, leveraging technology, such as IoT sensors for real-time monitoring, can provide immediate alerts for potential issues, contributing to proactive rather than reactive maintenance strategies. By adopting these practices, companies can ensure their CNC laser cutters remain reliable and efficient assets in their production processes.